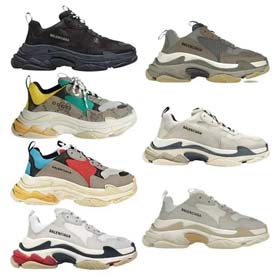

How Joyabuy's Quality Control Spreadsheet Ensures Sneaker Buyers Make Informed Decisions

For sneaker enthusiasts and resellers, quality inconsistencies can be frustrating. Joyabuy has implemented an innovative solution - a detailed QC (Quality Control) spreadsheet that tracks every aspect of production, from initial inspection to final resolution of any issues.

This transparent system is changing how buyers assess Joyabuy Jordan sneakers

The Power of Transparent QC Tracking

Every batch of Joyabuy Jordan sneakers undergoes rigorous inspection, with findings meticulously documented in their spreadsheet system:

- Detailed defect identification:

- Quantified quality metrics:

- Action tracking:

- Quantified quality metrics:

Real-World Example: Batch #JX429 Quality Resolution

The system's value became particularly apparent with Batch #JX429 of the Air Jordan 1 Retro High. The QC spreadsheet revealed:

| Issue | Affected Units | Resolution |

|---|---|---|

| Slight color variation on toe box | 14% of batch | Materials reprocessed, corrected in subsequent batches |

| Inconsistent sole thickness | 7% of batch | Mold calibration improved, affected units removed |

Strategic Benefits for Buyers

This level of detail provides several advantages:

- Predictable quality:

- Time-sensitive decisions:

- Comparative analysis:

- Verification tool:

- Time-sensitive decisions:

A New Standard in Sneaker Commerce

The Joyabuy QC spreadsheet transforms buying from a gamble into an informed decision. As this system evolves, expectations continue to rise - when buyers can review QC information directly from Joyabuy, purely guessing at product quality becomes unacceptable.

For serious collectors and resellers, this documentation provides not just purchase confidence, but valuable records for future reference and authentication purposes.